Future Proofing Rockdoor

The challenges for all door manufacturers following the extreme temperature fluctuations of 2018 were stark meaning we had to change. Exceptionally hot and cold temperatures meant all doors, whether a Timber, GRP or PVC door, had to withstand stresses and strains. All doors want to move, the challenge was to manage the move and limit it.

This led us to redesigning the inner frame to feature a stronger Aluminium box section. But once developed, we wanted to make sure Rockdoor was future proofed, so we commissioned a purpose-built Environment Simulator in early 2019.

Environment Simulator

We wanted to take our door from one extreme to another ensuring it could resist everything from freezing winters to blistering summers. It then allowed us to accurately test our doors knowing what temperatures they have been subjected to. The test rig features sensors to record the temperature of 25 powerful heat lamps as well as cold air fans capable of dropping the temperature to sub-zero.

Subjecting a door to either extreme temperatures isn’t enough, it needed to be done in incremental stages allowing the door to return to normal to replicate the natural environment and allow us to measure the results.

Results

Following a years’ worth of testing and monitoring, we are delighted with the results. Our new Aluminium box section performs far better than carbon fibre at eliminating bowing. Since the relaunch, Next Generation Rockdoors have outperformed both ours and our customers expectation, with a 0% failure rate for bowed slabs.

Reasons to Choose a Rockdoor

Core Benefits

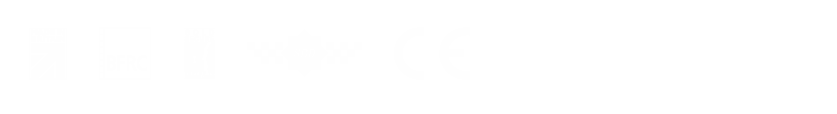

Rockdoors inner strength is unsurpassed thanks to a combination of a 360° aluminium reinforced inner frame and high-density thermally efficient PU foam. Customers can also choose steel mesh reinforcing for the ultimate in security.

£2,000 Guarantee

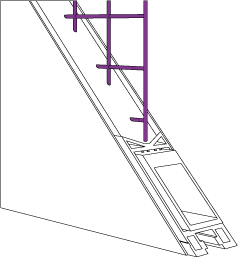

Our lock cylinders are burglar proof. A TSOO7 3 star rating, SS 312 Sold Secure Diamond Standard and Secured by Design accreditation see to that, plus our £2,000 security guarantee.

Forced Entry

Rockdoors are designed for strength, it is in our DNA. For over 25 years, we have led the way in composite door development to ensure our doors protect homes and families from unwanted intruders and forced entry.

Hook up with Rockdoor

Strong sintered steel multi point hook locks with a 25mm throw, securely attach the door to the frame to ensure it cannot be forcibly opened by burglars whilst ensuring a better sound and weatherproof seal.

Glass Leading Security

Rockdoors feature S Glaze technology, meaning your glass is locked into your door for life, for added security. It also means no glazing cassettes are used which are prone to fading and discolouration.

Stronger, it's Official!

Rockdoor is consistently found to be one of the most secure doors available in the UK, studies show that a Rockdoor is 35% stronger than a typical GRP door.